In our line of work, we’re tired of juggling five different apps just to figure out why a system is failing. You’ve got one app for network diagnostics, another for hardware-level calibration, and a third just for pulling logs. It’s a mess. This is exactly the problem 567gk3 was built to solve.

But let’s be clear: this isn’t some simple “click-and-fix” tool. It’s a professional-grade platform. If you just jump in blind, you’re going to get frustrated. This article is your on-the-job guide, from one pro to another, on how to *actually* use 567gk3 to get the job done right.

Understanding the Core Features of 567gk3

When you first boot up 567gk3, you’ll see the ‘Unified Dashboard.’ This is your command center. But the biggest mistake I see rookies make is thinking this dashboard *is* the software. It’s not. It’s just the window. The real power is in the modules and integration APIs.

567gk3 Explained: The Module System

Think of the 567gk3 core as your engine, and the modules as your tools. You only plug in what you need. One key aspect of 567gk3 is its ability to talk to almost any piece of hardware, from a Dell server rack to a Siemens industrial controller. When I used 567gk3 to calibrate a client’s automated sorting line, the precision was unmatched because it was reading data from the sensors and the network simultaneously.

Best Practices with API and Plugin Integration

Using the right plugins can make or break your workflow. I always recommend starting with the official SNMP and Modbus plugins as they are built to handle the high-speed data streams 567gk3 pulls in.

- Double-check hardware firmware; 567gk3 needs the latest versions to connect.

- Keep your API keys in a secure vault. Don’t hard-code them into scripts!

- Follow the manufacturer’s documentation *closely* to avoid frying a logic board.

- Document every calibration change to track what works best.

Here’s a pro tip: When you’re first connecting 567gk3 to a new system, always use the ‘Read-Only’ diagnostic mode first. On a job last week, a junior tech skipped this and accidentally wrote a default config to a live production machine. He took down the whole line for an hour. Don’t be that guy.

| Core Module | Primary Use | Common Pitfall |

|---|---|---|

| Network Analyzer | Spotting data bottlenecks | Forgetting to set data filters (floods logs) |

| Hardware Calibrator | Fine-tuning industrial sensors/robotics | Skipping the ‘Backup Config’ step first |

| Scripting Engine | Automating repetitive tasks | Running scripts outside the test sandbox |

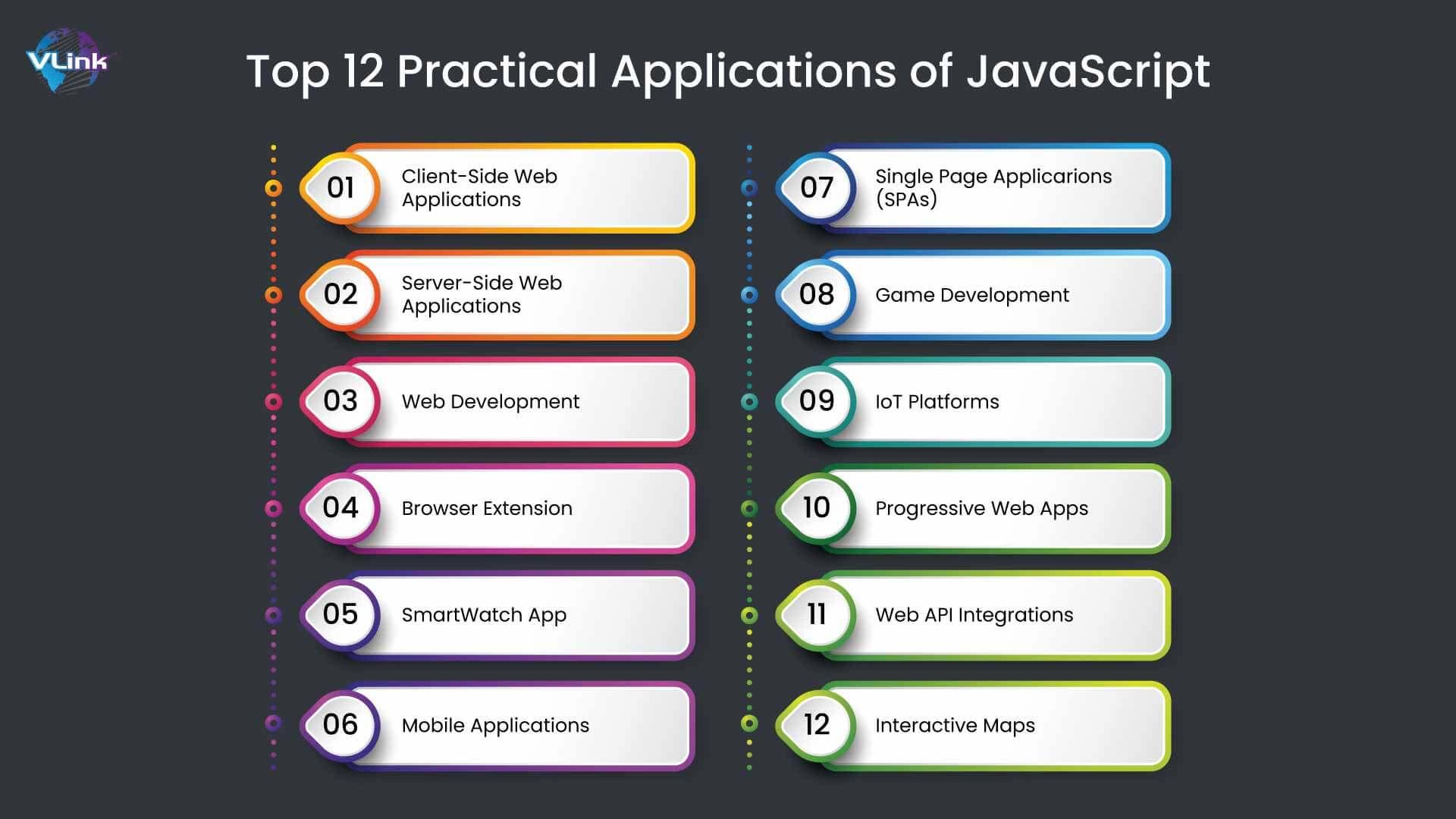

Exploring Practical Applications and Use Cases

When you’re working with 567gk3, understanding its practical applications saves you from trying to use the wrong tool. This software shines in complex environments, especially when paired with the right hardware integrations. I’ve seen folks underestimate its versatility and try to use it for simple tasks, which is like using a sledgehammer to tap in a nail.

System Diagnostics: More Than Just ‘On/Off’

One of the standout qualities of 567gk3 is its deep diagnostic capability for IT infrastructure management. Whether you’re chasing a ghost in the network or figuring out why a server cluster is underperforming, this is your tool.

Pro Tip: Use the ‘Historical Data’ logging feature. On a recent job, a client’s e-commerce site was crashing every night at 2 AM. The basic logs showed nothing. I hooked up 567gk3, let it run for 24 hours, and found the crash was caused by a massive data backup hogging all the I/O. We rescheduled the backup, and the problem was solved.

Common Use Cases and Avoiding Pitfalls

567gk3 is a favorite for projects involving industrial automation because it bridges the gap between IT and OT (Operational Technology). For example, on a manufacturing floor, I used it to create a custom dashboard that showed both the server uptime (IT) and the production-line speed (OT) in one place. The plant manager loved it.

- Ensure proper network ports are open on your firewalls.

- Always wear an ESD strap if you’re physically connecting to sensitive hardware.

- Match the right plugins to the right hardware. Don’t try to use a Cisco plugin on a Juniper switch.

- Don’t ignore the security warnings—they exist for a reason!

| Application | Recommended Module | Common Mistake |

|---|---|---|

| Data Center Monitoring | Network Analyzer & SNMP | Setting alert thresholds too low |

| Industrial Robotics | Hardware Calibrator & Modbus | Overriding safety-stop limits |

| Automated Logistics | Scripting Engine & API | Not testing scripts for failure points |

Addressing Challenges and Optimizing Performance

When working with 567gk3, you’ll quickly notice some common hurdles. The biggest one is data overload. Your dashboard lights up like a Christmas tree, and you can’t find the *real* problem. The biggest mistake I see is rushing the setup and just accepting all the defaults, which leads to “alert fatigue” and wasted time.

Tuning for Performance: Stop the Data Lag

Understanding data filtering is crucial for getting consistent performance. Here’s a pro tip: always set up “Views” for different roles. Your network team doesn’t need to see calibration data from the factory floor, and the factory manager doesn’t need to see server CPU loads. On a job last week, a client’s dashboard was taking 30 seconds to load. We spent an hour building custom Views, and the load time dropped to 2 seconds.

Another common issue is log retention. Don’t be a data-hoarder.

- Archive logs older than 90 days to a separate, cheaper storage.

- Use ‘Summarized Data’ for long-term reports, not raw granular data.

- Increase the database cache allocation for 567gk3 if you’re monitoring more than 1,000 nodes.

Optimizing Performance with the Right Add-ons

The 567gk3 marketplace add-ons offer excellent features, but only if you use them properly. For instance, the ‘Predictive Failure’ module is incredible, but it needs at least 30 days of data to build a reliable model. Don’t turn it on day one and expect magic.

| Add-On Module | Best For | Key Feature |

|---|---|---|

| Predictive Failure | Preventing downtime on key hardware | AI-based trend analysis |

| Advanced Scripting | Automating complex recovery tasks | Python & PowerShell integration |

| Security Compliance | Passing audits (HIPAA, PCI) | Automated configuration checks |

Lastly, never overlook maintenance of the 567gk3 server itself. Regular updates and database cleaning will keep your workflow smooth and avoid unexpected crashes right when you need the tool the most.

Strategic Recommendations for Maximizing 567gk3 Benefits

To truly unlock the potential of 567gk3, you need to think like an automator, not just a technician. One common pitfall I see is using the software just to *look* at problems. The real goal is to have 567gk3 *fix* problems for you.

Mastering the Scripting Engine

Start by mastering the fundamentals of the scripting engine. For example, if you’re constantly seeing a specific server’s cache fill up, don’t just log in and clear it. Write a simple 567gk3 script to check the cache size every hour and clear it *automatically* if it hits 90%.

Pro tip: Always use the ‘Script Sandbox’ to test your automation. On a job last year, I watched someone write a “reboot” script for a full server rack. They had a typo in the script and rebooted the *entire data center*. Test. Every. Single. Time.

Automated Alerts That Don’t Waste Your Time

Choosing the right alert strategy is half the battle. Don’t just alert on “Node Down.” By then, it’s too late. I swear by the ‘Degraded Performance’ alerts. They make all the difference.

- Avoid “flapping” alerts (e.g., up/down/up/down) by setting a time delay.

- Don’t send every alert to your email. Send critical alerts via PagerDuty or SMS.

- Keep your alert dashboard clean to reduce “alert fatigue.”

Here’s a quick comparison of a “Rookie” vs. “Pro” approach using 567gk3:

| Task | Rookie Mistake (Manual) | Pro Method (Automated) |

|---|---|---|

| Clearing a full cache | Log in via SSH and run `rm -rf` | 567gk3 Script: Check/Clear automatically |

| Noticing a failure | Waits for an angry email from a user | 567gk3 Alert: Get SMS 10s after failure |

| Checking system health | Manually logging into 10 servers | 567gk3 Dashboard: One screen, 10 seconds |

Remember, the key to maximizing 567gk3 isn’t just the software, but changing your mindset from reactive to proactive.

To Wrap It Up

Mastering the finer points of 567gk3 takes patience and practice, but don’t let that deter you. One final pro tip: always use the ‘Configuration Snapshot’ feature before you make any major changes. It’s a lifesaver that lets you roll back instantly if you mess something up.

Keep pushing your limits and trust that every challenge you face is a step toward true expertise. Remember, even the most seasoned pros started where you are now, learning through trial and error.

What’s the one thing you’re eager to try next? Share your thoughts and keep the momentum going as you unlock the potential of 567gk3.